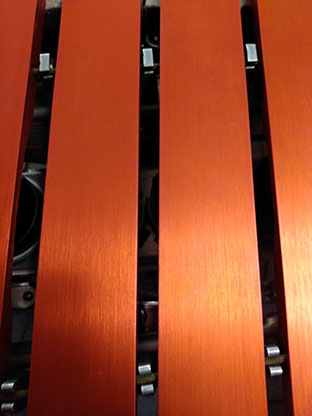

We then only lightly brushed our bars by hand with standard polishing mats in the longitudinal direction in order to obtain a reasonably uniform and not too reflective surface. The resulting surface structure remained visually very pleasant even after anodizing.