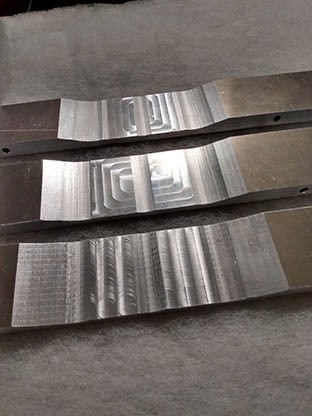

Schritt 4: Milling

Since we wanted to carry out the milling work on the machines in our university, we also had to create the program for the control of the milling machine ourselves. We have defined suitable milling operations in the manufacturing module of our CAD system:

-

Roughing with an end mill

-

Finishing with a ball mill

There are large numbers of qualified companies, at least in Germany.

Before anodizing, we easily removed the small burrs along the milling marks with a belt sander. The subsequent control of the frequencies brought an excellent agreement with the previously simulated values.