Then the actual anodizing takes place in the electrolytic process in sulfuric acid or oxalic acid electrolytes with the application of a direct voltage. After anodizing, the dyeing and then compacting takes place in a hot water bath. The duration of remaining in the compression bath depends on the anodized layer thickness generated, i.e. on the duration of remaining in the anodized bath.

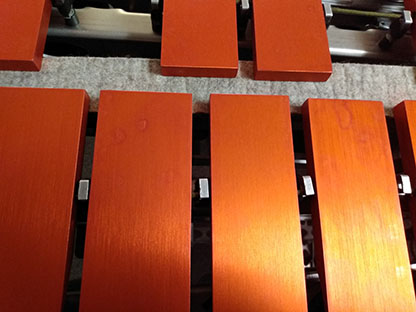

For the most part, this worked very well, only the time in the compression bath was a little too short, so that the paint is still a little bled out in some places.

Overall, however, we were only able to determine small changes in the sound spectrum due to anodizing for the red plates.