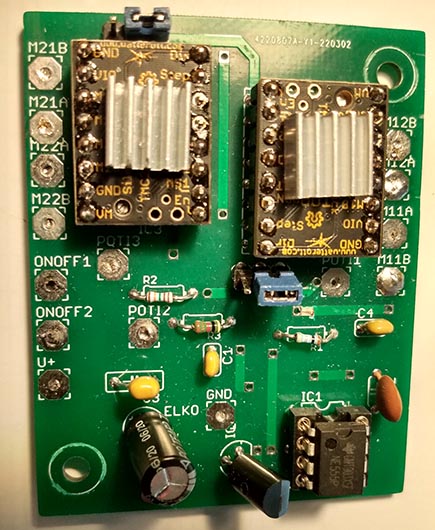

Vibraphone motor unit with infinitely variable speed control

Stepper motors have the advantage over the usually used gear motors in

vibraphones that they have much less weight and can be operated with a lower

supply voltage of 12 V. Their disadvantage is usually that the stepper operation

causes noise.

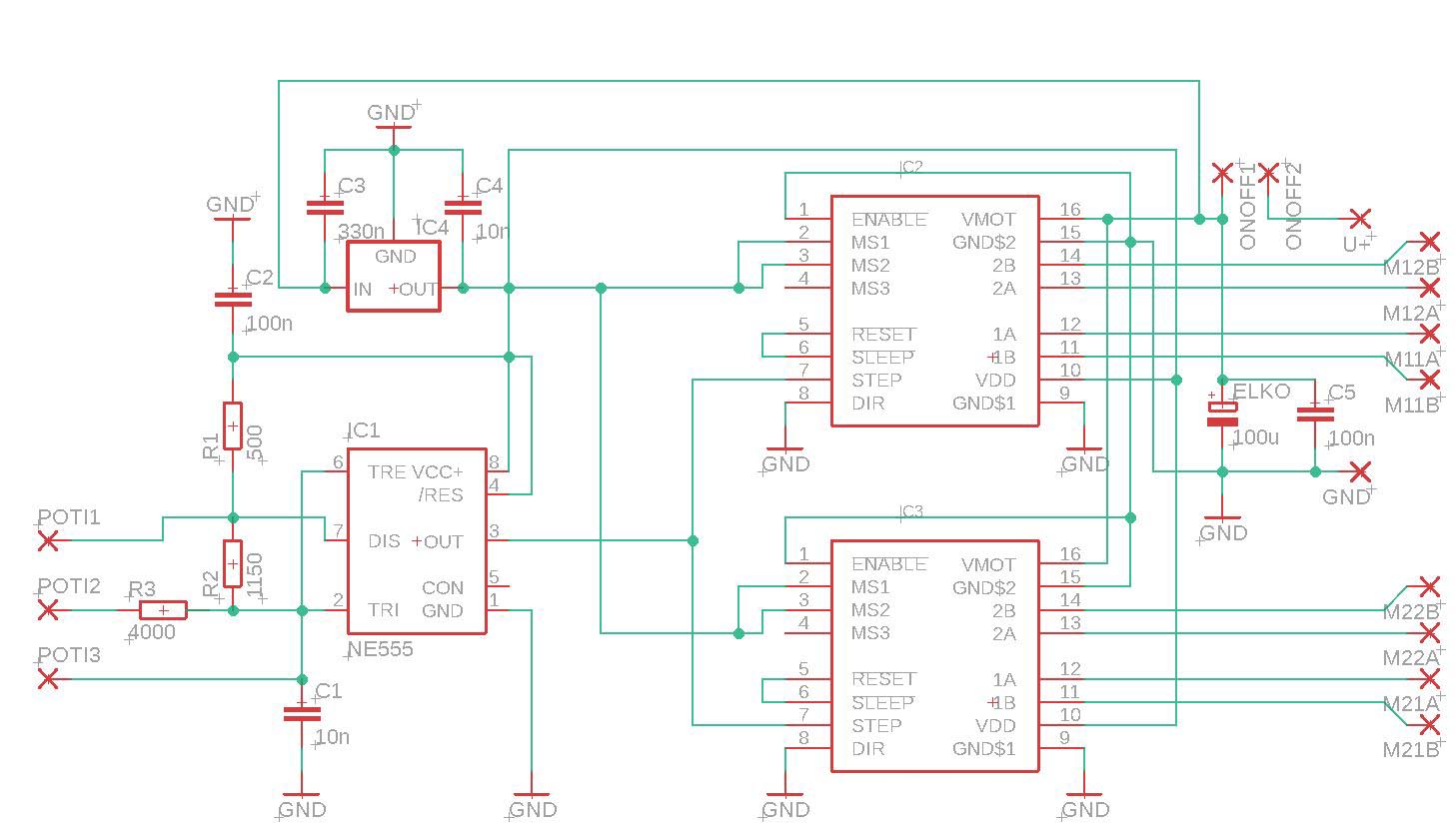

Therefore, I have used drivers for my control that allow a significant reduction

of the noise excitation via a so-called StealthChop.

https://www.trinamic.com/technology/motor-control-technology/chopper-modes/#c3044

In connection with a high-quality stepper motor (Wantei 42BYGHW811) and an elastic motor suspension I could reduce the noise of the motor to a large extent. However, they cannot be prevented completely, but they can usually be shifted by setting the control to unused speeds.

The controller is able to drive two stepper motors synchronously at the same

time, because I use one motor per resonance tube row for the folding frames.

The two jumpers can be used to define the direction of rotation for each

motor.

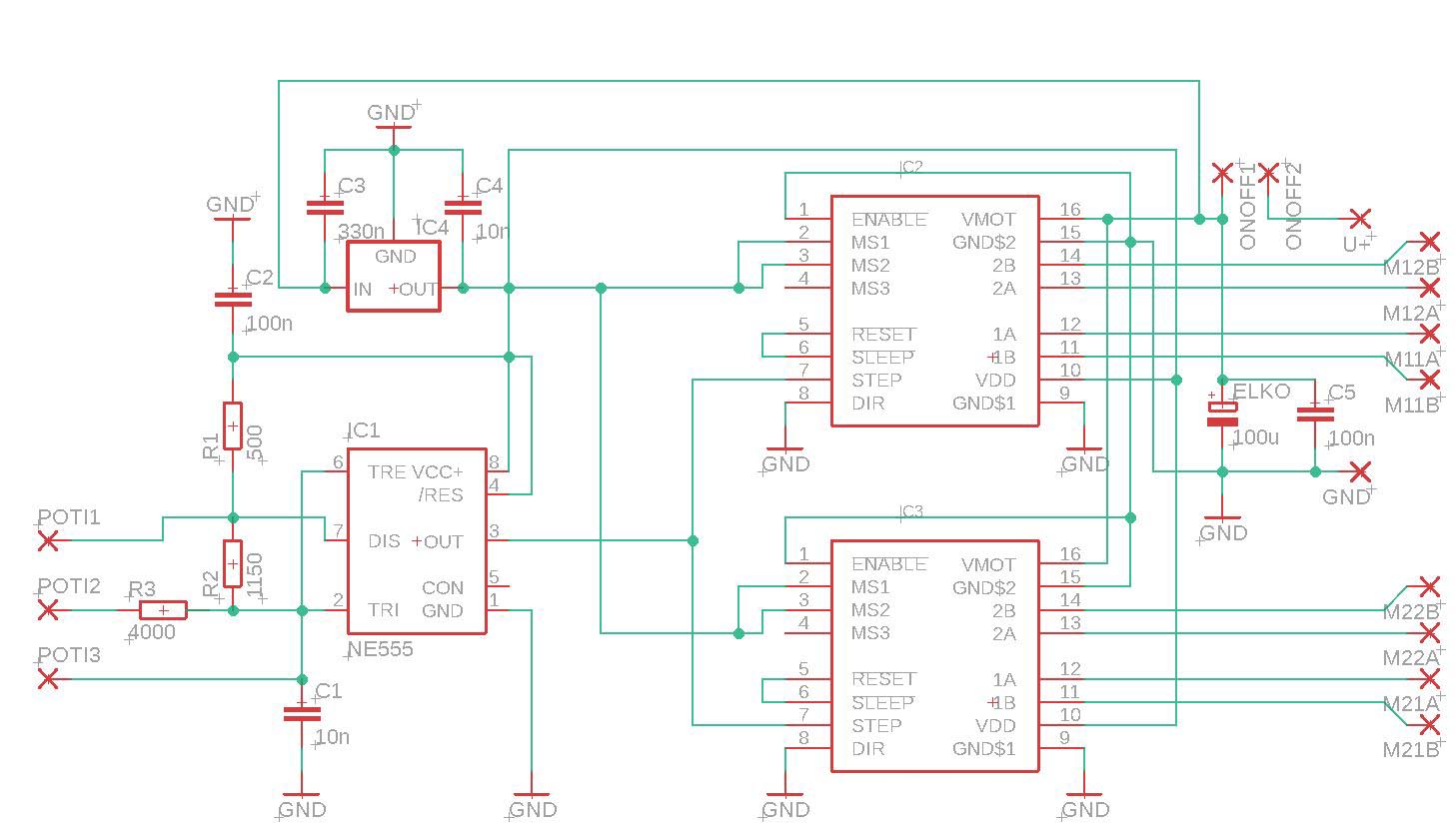

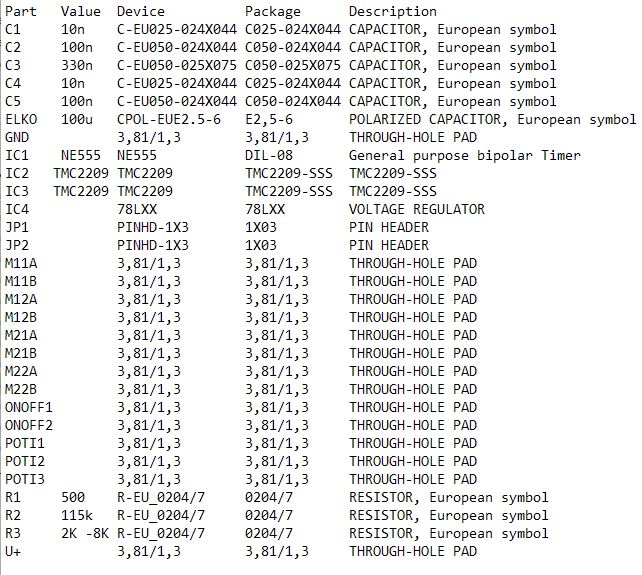

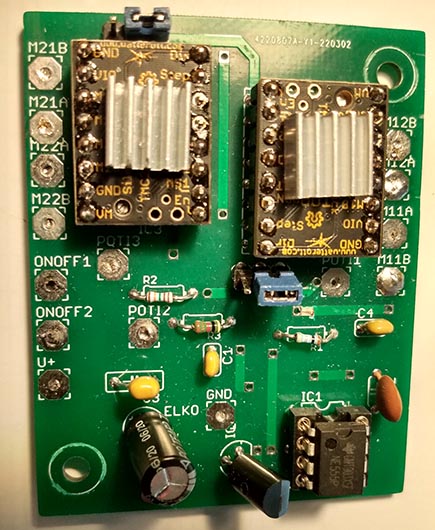

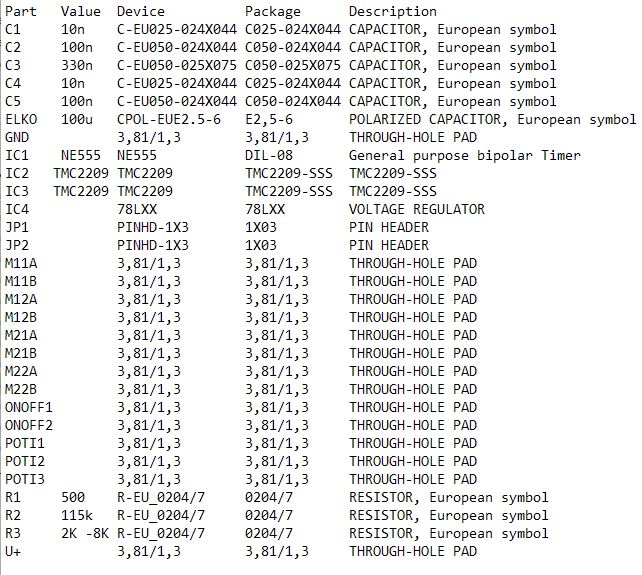

Below I have attached the schematic and the parts list of the control, as well as the STL file for the elastic mount for an M55. The material costs for motors including control and housing are about 150 € (as of Dec. 2022). But you need a few hours to solder and work on the housing. Currently (Dec. 2022) I still have 8 unassembled boards lying around.

Motor-Adapter for Musser M55 I use for 3D printing the material Ultrafuse TPC 45D from BASF.

|

|

|

|

|

|