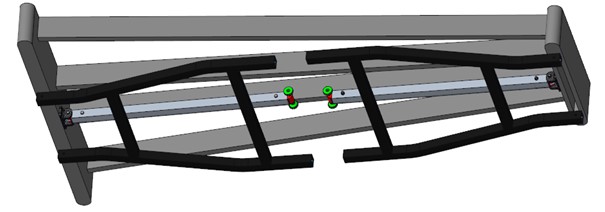

Frame stabilization for older M55 vibraphones

I have here two simple and inexpensive, but very effective

and easy to realize solutions for frame stiffeners on old Musser M55 vibraphone

frames. All you need are a few easy-to-source 3D printed parts, two pieces of

aluminum square tubing and a few nuts and bolts.

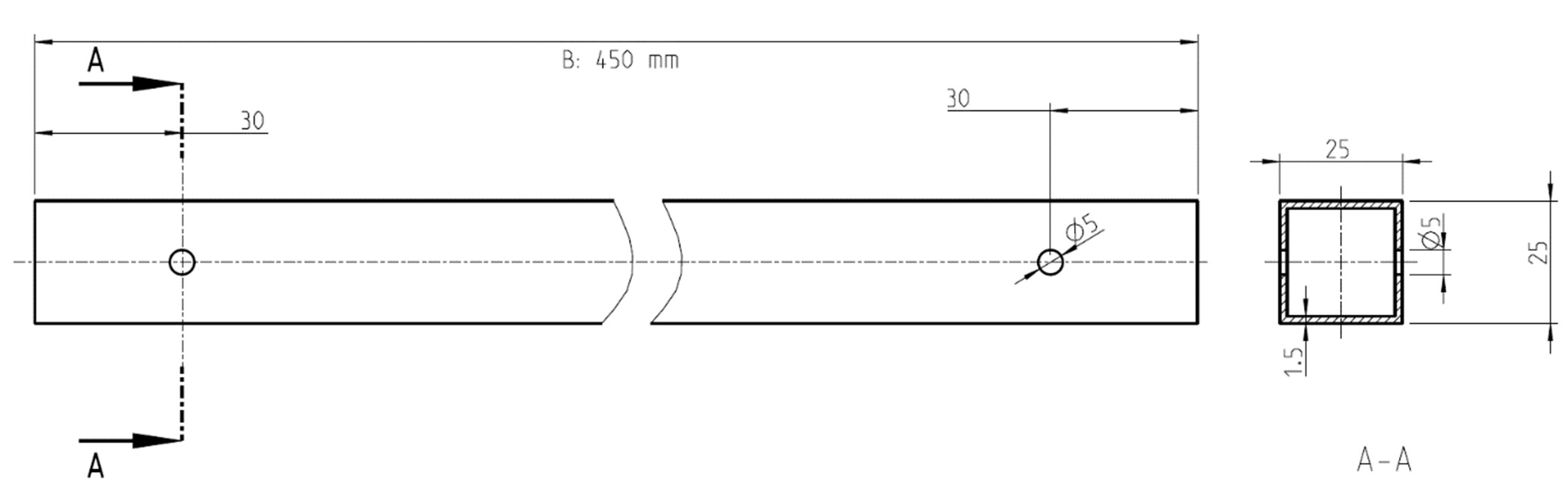

Drill a 5.0 mm diameter hole 30 mm from the cut edge at both ends of the 25 mm x

25 mm x 1.5 mm aluminum square profiles (commercially available DIY store

goods).

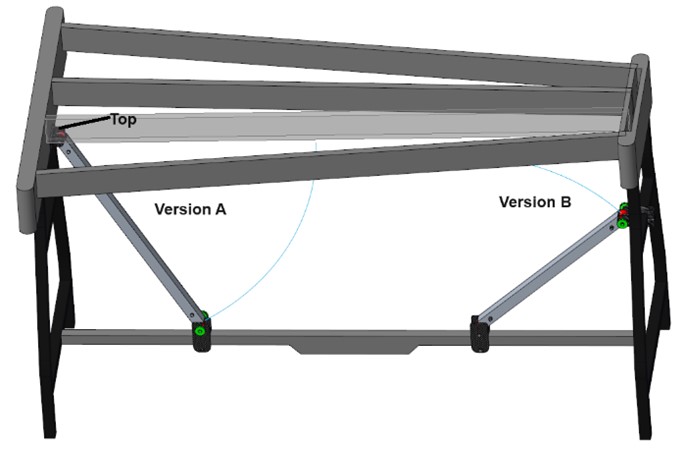

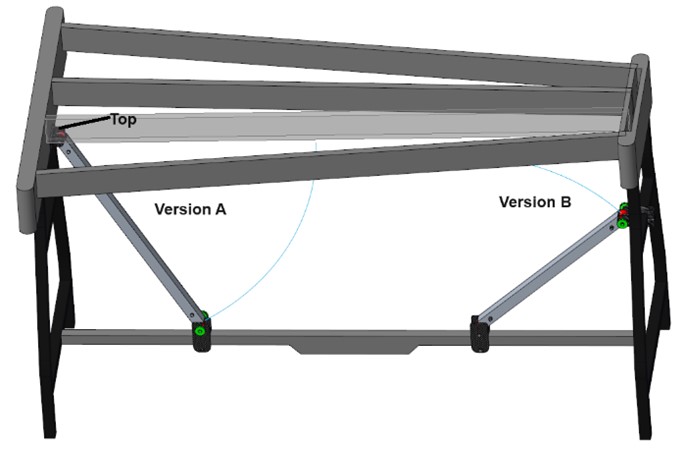

Version A is more stable and more

convenient for dismantled frame transportation, as the outriggers can be folded

in with the side parts.

Download the 3D

printed parts for

version A here.

Version B does not require any

modifications to the original vibraphone frame, as all components are simply

clamped.

Download the 3D

printed parts for

version

B here.

The structure and function of both variants are shown in the following illustrations.

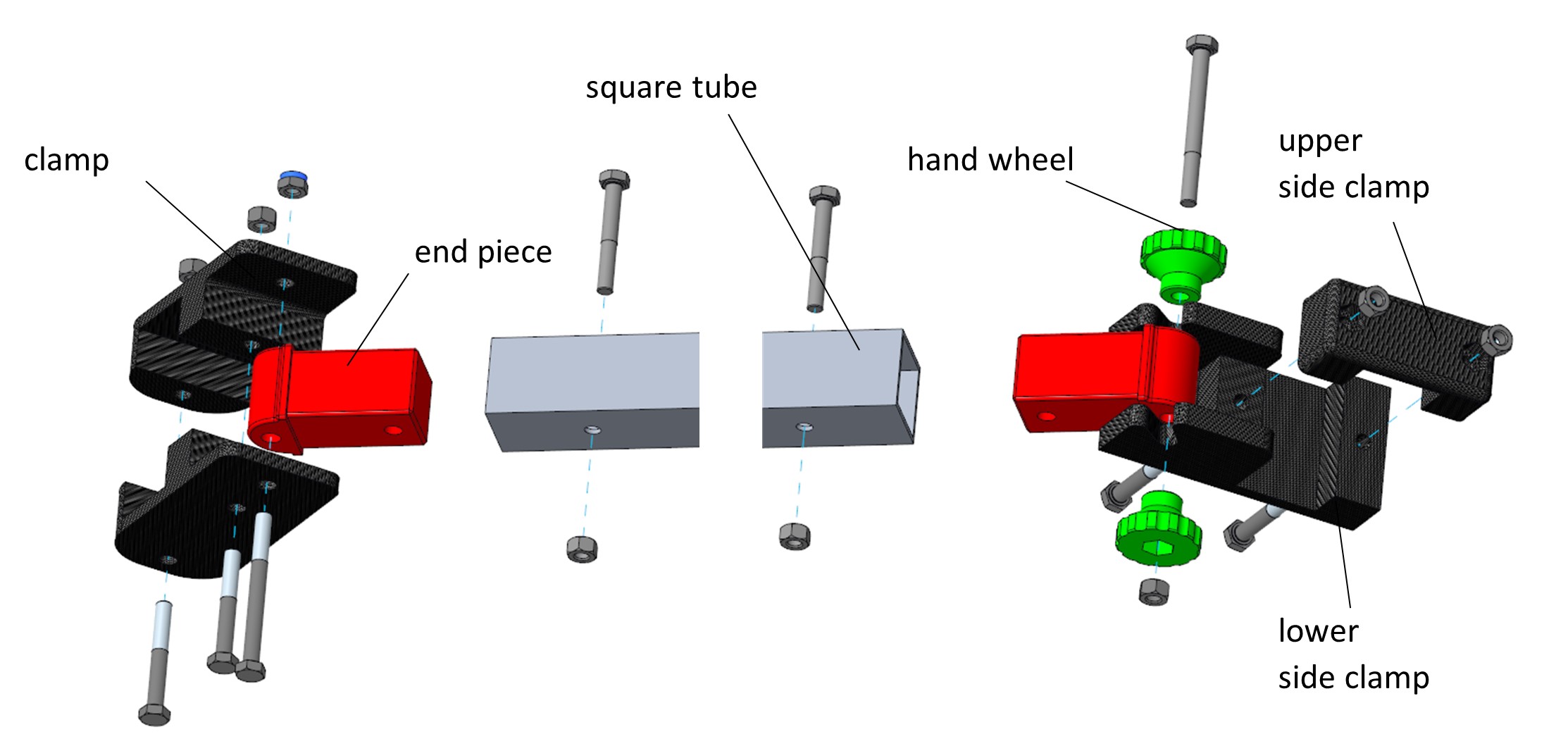

Version A

Tube length square tube: 580 mm

For version A, the two clamp half shells

are placed on the pedal bar and lightly screwed together (ISO 4014 M5x35 and nut

ISO 4032-M5) so that the clamp can still be moved on the pedal bar. The two end

pieces are then inserted into the tube and screwed together with ISO 4014-M5x45

screws and ISO 4032-M5 nuts. On one side, the pivot bearing is screwed in place

with a screw ISO 4014-M5x45 and a nut with clamping part ISO 10511 so that it

can rotate easily but is free of play. On the other side of the cross strut, a

screw ISO 4014-M5x50 is inserted through the first handwheel, then through the

free end piece and further through the second handwheel. Then screw on another

ISO 4032-M5 nut.

To mount the pre-assembled cross strut to the frame, the side with the two

handwheels is inserted into the groove of the clamp and lightly fixed in place

by tightening the handwheels. By moving the clamp on the pedal beam, the

position is changed until the lower edge of the pivot bearing is flush with the

lower edge of the wooden frame. The pivot bearing is now mounted in the frame

using wood screws.

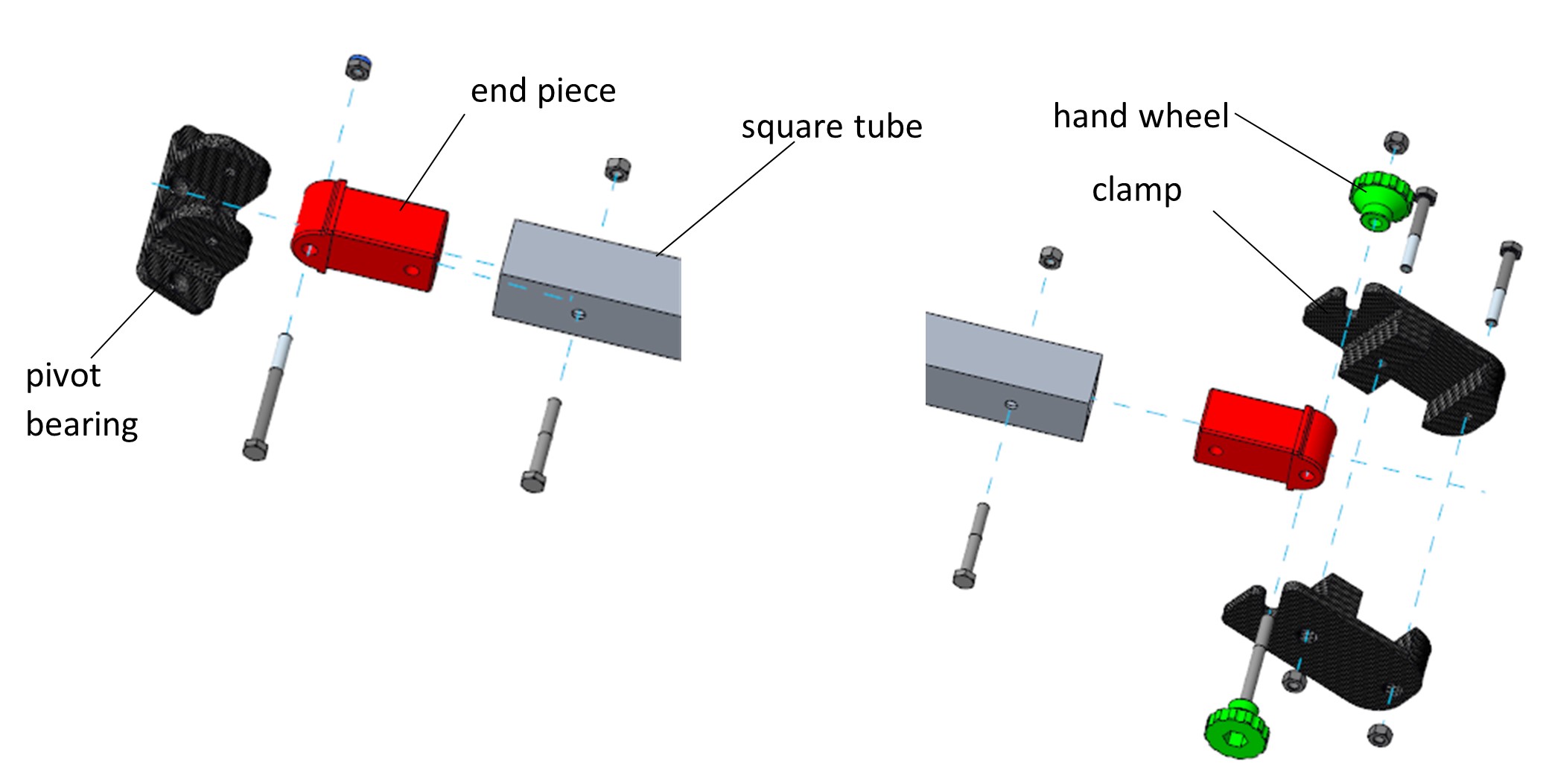

Version B

Tube length square tube: 450 mm

For version B,

the two clamp half shells are placed on the pedal bar and lightly screwed

together (ISO 4014 M5x35 and nut ISO 4032-M5) so that the clamp can still be

moved on the pedal bar. The two end pieces are then inserted into the tube and

screwed together with ISO 4014-M5x45 bolts and ISO 4032-M5 nuts. One side of the

cross strut is screwed into the clamp using a screw ISO 4014-M5x45 and a nut

with clamping part ISO 10511 so that it can be easily rotated but is free of

play. On the other side of the cross strut, a screw ISO 4014-M5x50 is inserted

through the first handwheel, then through the free end piece and further through

the second handwheel. Another ISO 4032-M5 nut is then screwed on.

The lower and upper side clamps are placed on the crossbar of the vibraphone

frame and screwed together with two M5x35 screws and an M5 nut so that the side

clamp can still be moved.

The exact position of both clamps is determined by inserting the pre-assembled

cross brace into the groove of the side clamp and fixed by tightening the

screws.