Step 6: Anodizing

Since all usable materials have poor weather resistance and form oxide layers when in contact with oxygen, the sound bars must be anodized. Unfortunately, all of the materials mentioned are largely unsuitable for decorative anodizing.

Before the actual anodizing process, the parts are pickled in a lye solution. Depending on how long they remain in the bath, this results in a greater or lesser amount of material being removed from the surfaces.

This is followed by the actual anodizing process, which is carried out using an electrolytic process in sulfuric acid or oxalic acid electrolytes with the application of a direct current voltage.

After anodizing, the material is dyed and then compacted in a hot water bath. The length of time spent in the compaction bath depends on the thickness of the anodized layer produced, i.e., on the length of time spent in the anodizing bath.

Since we cannot carry out this process at the university, we did not have 100% control over the process. We worked with the company to make the material stripping and the subsequent anodized layer as thin as possible in order to minimize sound changes caused by the anodizing process.

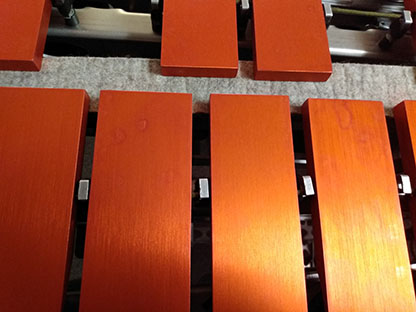

This worked very well for the most part, but the time in the densification bath was a little too short, so that the color bled a little in some places afterwards.

Overall, however, our measurements showed only minor changes to the sound spectrum of the red bars as a result of the anodizing.

Since we were not sure about this at the beginning, we had reserved some extra material for readjustment.

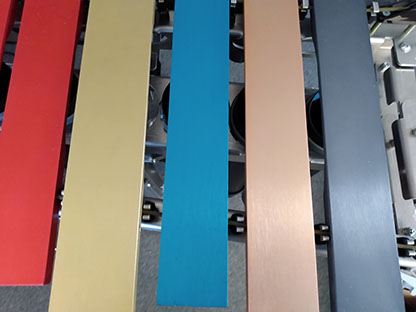

We tried several colors. With the color blue, for example, the anodizing had to be done for much longer to achieve an intense color, which resulted in greater changes to the frequency spectrum than with most other colors.