Suitcase Frame

The case frames were developed with the aim of minimizing transport volume while also minimizing packaging dimensions.

Of course, the case frame does not have to be completely dismantled for every transport. The frame fits well into a keyboard bag together with the folded base frame and the unfolded carrying frame.

Download Frame Data

All components for manufacturing a 3D frame for Musser M55 bars are included in the following download in STEP format.

- Stp-Data for 3D-Printing (complete frame including resonance tube units)

- Instructions for using the Step Tools

- Free software for reading step data (Step Viewer)

- Free CAD software (which can also be used to take measurements in Step data)

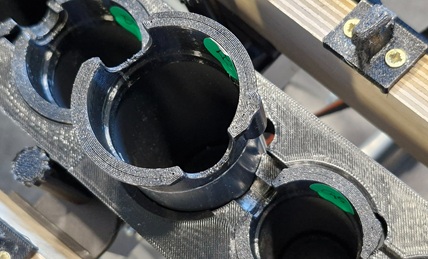

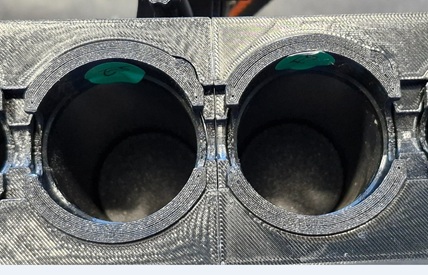

"Tube- in - Tube" - Concept

With the “tube-in-tube” concept, up to four resonance tubes can be packed nested inside each other for transport by air or rail.

For resonance tubes made of aluminum or PVC, a maximum of three tubes can usually be nested inside each other due to the gradation of the tube diameters. A 3D-printed head piece must then be glued to each tube for positioning and mounting in the tube holder, or alternative fixing methods (features for aluminum) must be used.

The longer resonance tubes are printed in two parts and then glued together.