Bar Posts

Over time, I have used a variety of different bar post designs, but always with the aim of dampening as much of the impact pulse against the frame as possible.

- I started with rigid screw bar posts with a rubber insert for the cord feed-through. However, this has the disadvantage that the bars cannot be removed or replaced, or only with great effort.

- The aluminum bar posts on rubber buffers are very good, but also very costly to manufacture, as a thread must be added to the narrow aluminum element (laser cutting).

- The EPDM bar posts require a slotted mount (aluminum strip) on the frame, which adds additional weight. Water jet cutting is also a high cost factor. However, these bar posts are very comfortable to play and have very good impulse damping properties.

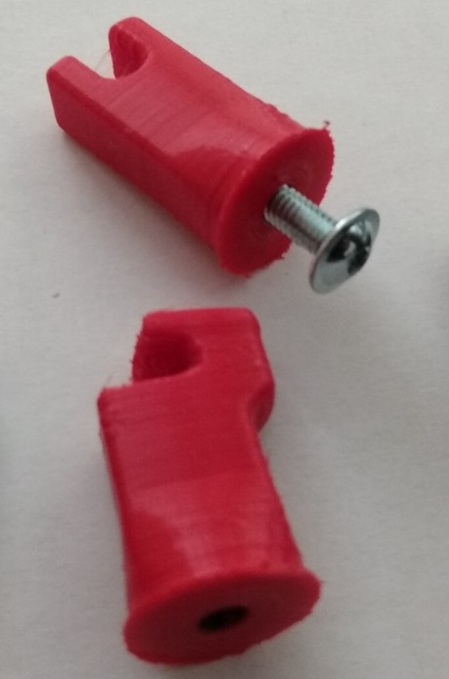

- The 3D-printed bar posts with integrated nuts are very well suited for pipe or sheet metal frames, but the interrupted printing process for inserting the nuts is quite time-consuming.

3D printed bar posts

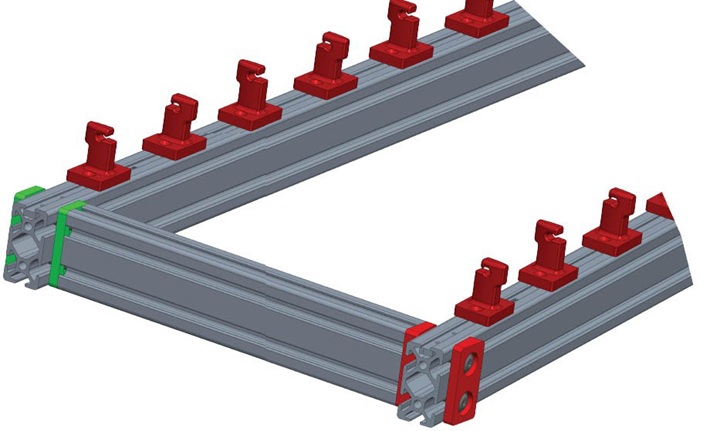

In the end, hook-shaped bar posts printed from TPU proved to be the most effective solution.

These can be used on any type of frame and, when arranged alternately, enable the sound bars to be transported safely on the frame (which is useful when using pickups), while at the same time allowing the bars to be easily removed and replaced as usual.

The 3D printing data for the plate holders is available for free download.