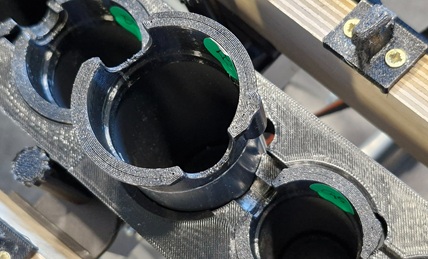

"Tube - in - Tube" - Concept

With the “tube-in-tube” concept, up to four resonance tubes can be packed nested inside each other for transport by air or rail.

For resonance tubes made of aluminum or PVC, a maximum of three tubes can usually be nested inside each other due to the gradation of the tube diameters. A 3D-printed head piece must then be glued to each tube for positioning and mounting in the tube holder, or alternative fixing methods (features for aluminum) must be used.

The longer resonance tubes are printed in two parts and then glued together.

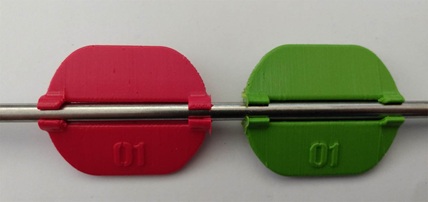

Flap Concepts

Various flap designs were tested. Starting with magnetically mountable, split flap units, several flap variants were developed:

- 3D-printed replacement flaps for clipping or gluing on without disassembly

- 3D-printed clamp flaps for sliding on for DIY projects

- 3D-printed, twistable flaps

Download the model data for the resonance tube units and flaps

The download includes the model data for an M55 resonance tube unit with fixed flaps for sliding on and with adjustable flaps (twistable flaps), as well as the tube holders that can also be used without the flap unit.

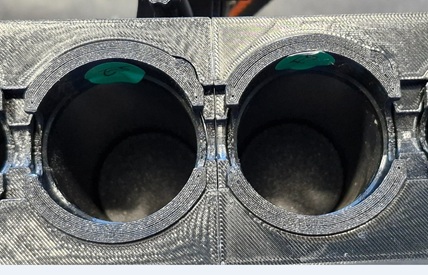

Foldable Resonance Tube Units

Various types of resonance tubes (aluminum, PVC, PETG printed) were used. Classic side plates with riveted tubes and plug-in holders made of aluminum and PETG 3D printed were used as resonance tube holders.

The plug-in variants are either foldable or, in the case of the 3D-printed ones, also separable.

Variants were also produced without any motor connection and with one motor connection per tube row. In the 3D-printed variant, the motor connection is removable.